Articles

The Science of Durability: Labels Built for the Harshest Environments

The Auld brand has been building brand identity elements (domed for more than 150 years). With that kind of history, you learn something important: durability is a commitment.

Since taking ownership, I have had the privilege of hearing from customers who share their experiences. Some tell me that long after their equipment has been retired, our labels are still holding strong. They have endured rain, heat, cold, and years of hard use. That is not by chance. That is by design.

Today I want to share how we make that possible—how we engineer domed labels, decals, and emblems to not only survive but perform in the harshest conditions.

What Durability Means to Us

When people think of a durable label, they often picture one that simply does not peel off. For us, durability means much more.

- Adhesion that does not fail in heat, cold, or moisture

- Inks that do not fade after years of exposure to the sun

- Surfaces that resist scratches, chips, and the everyday wear of real use

Most of all, it means your brand looks just as strong years from now as it did the day your product shipped.

Our Multi-Layered Approach to Strength

Durability starts with design, and no detail is too small.

- Specialty coatings and die cut finishing – Advanced coatings provide added protection while precision die cutting ensures a perfect fit

- Domed polyurethane coating – A clear resin creates depth and dimension while protecting your brand from fading and scratches. Once fully cured, any surface scratches or blemishes will work themselves out over the course of a few hours

- Custom shapes, sizes, and finishes – Every detail is customizable to reflect your brand identity

- Application specific materials – From adhesives to urethane, every choice is made to match your product’s environment, whether that means resisting UV exposure, chemicals, moisture, or impact

We do not settle for almost right. Every label is engineered to your specifications so it performs exactly as you need it to, now and for years to come.

Tested for the Real World

We do not just claim our labels last, we prove it. Our domed labels have passed an exhaustive list of performance tests, including:

- Extreme temperature cycling (hot, cold, humidity)

- Chemical resistance—including sunscreen, insect repellent, and industrial solvents

- Xenon Arc weatherometer exposure

- Post exposure adhesion and peel testing

- Impact, abrasion, and corrosion testing

- Fluid spotting, chip resistance, and environmental cycling

- Adhesion integrity across OEM standards—FCA, FORD, HONDA, GM

We validate performance to exacting standards like GMW14650, FCA MS CG 51, HONDA Hes A 1045 11, and FORD WSS M2P180D. We cycle our labels through heat, water, UV, abrasion, and chemical exposure.

Why Cutting Corners Costs More

I have seen what happens when companies choose cheaper materials or skip critical protections. Labels lift off in the field, graphics fade after a single season, and customers begin to question the quality of the product itself.

When that happens, you are not just replacing a label. You are repairing trust.

Engineering for Legacy

We may use advanced materials and testing equipment today, but our mindset is the same as it was generations ago when Auld produced enamel nameplates for the Model T. Back then, a nameplate was not just a marker. It was a statement of pride.

That remains true today. Every domed label, decal or emblem we make is designed to honor your brand, protect it, and carry it into the future.

You Don’t Need to Be a Fortune 500 Company to Look Like One

When people think about premium branding, they usually think about the big guys — the household names with huge budgets [...]

The Top 10 Mistakes People Make When Using Custom Emblems or Decals

When it comes to custom emblems, domed labels, and decals, small details make a big difference. Over the years I have seen [...]

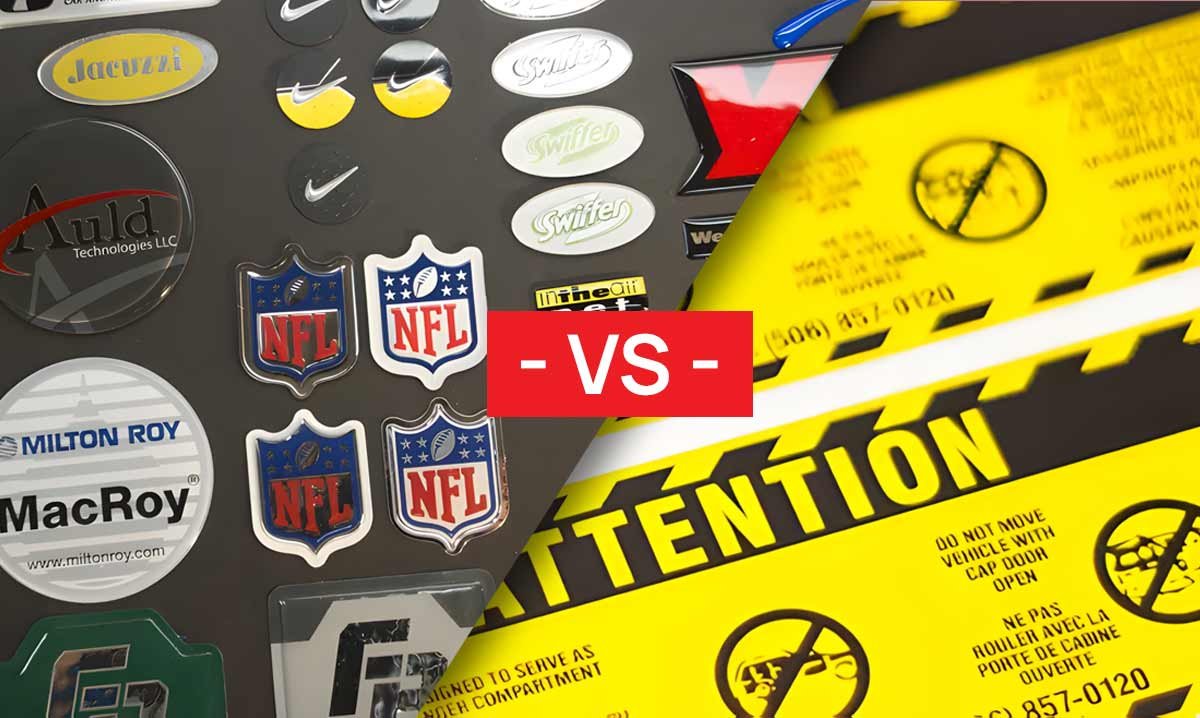

Domed Labels vs Flat Decals: Choosing the Right Option for Your Application

One of the most common questions I get is simple on the surface but important in practice. Should I use a domed label or a flat decal? [...]

Back

Back