Articles

The Top 10 Mistakes People Make When Using Custom Emblems or Decals

(and How to Avoid Them)

When it comes to custom emblems, domed labels, and decals, small details make a big difference. Over the years I have seen companies invest thousands in their branding only to lose impact because of simple oversights such as choosing the wrong material, skipping proper surface preparation, or overlooking how the environment affects performance.

The good news is that all of these mistakes can be avoided. Whether you are branding vehicles, equipment, or retail products, here are the top ten mistakes I see most often and how to make sure your custom emblems and decals look professional and last.

Mistake 1: Choosing the Wrong Material for Your Custom Emblems or Decals

Not all decals or emblems are created equal. The right material depends on where it will be applied, what it is adhering to, and how long it needs to last.

I often see companies use standard vinyl decals outdoors where a domed emblem or UV resistant material would have performed much better. Domed labels provide a premium appearance and exceptional durability, making them ideal for long term applications.

If you are unsure which option fits your needs, consult your manufacturer. A quality partner can match the correct material to your environment and application.

Mistake 2: Ignoring Surface Preparation Before Applying Decals or Labels

Surface preparation is one of the most important steps in any application. If the area is not properly cleaned and dried, even the best adhesive can fail. Oils, dust, and moisture create barriers that weaken adhesion.

Before applying any custom emblem, decal, or domed label, clean the area with isopropyl alcohol and allow it to dry completely. Proper preparation ensures a lasting bond and a professional appearance.

Mistake 3: Applying in the Wrong Conditions

Temperature and humidity play a bigger role than most people realize. Applying decals in extreme heat, cold, or moisture can affect how the adhesive bonds. Most adhesives perform best between 60 and 80 degrees Fahrenheit.

If you are applying your custom decals outdoors, aim for early morning or late afternoon to avoid temperature swings. The right conditions make a huge difference in the final result.

Mistake 4: Overlooking Brand Consistency in Your Emblems and Decals

Your emblems and decals represent your brand in the physical world. Mismatched finishes, inconsistent colors, or poorly scaled logos can weaken brand recognition.

Whether you use chrome emblems, domed decals, or printed labels, consistency in color, texture, and finish builds trust and helps your products stand out.

Mistake 5: Not Considering the Environment Where the Decal Will Be Used

The environment where your emblem or decal will live directly impacts its performance and lifespan. Sun exposure, moisture, cleaning chemicals, and physical abrasion can shorten product life.

If your application involves outdoor exposure, marine conditions, or industrial use, choose durable domed labels or polyurethane coatings that are built for long term resilience.

Mistake 6: Using the Wrong Adhesive Type

There is no universal adhesive that works for every surface. The wrong adhesive can cause bubbling, peeling, or even surface damage.

For example, metal, plastic, and powder coated surfaces all require different adhesive systems. When ordering your custom decals or emblems, always confirm the surface type so your supplier can recommend the correct adhesive for lasting performance.

Mistake 7: Forgetting About Proper Application Tools

Installing decals correctly takes more than just peeling and sticking. The right tools such as a squeegee, masking tape, and a heat gun help ensure a smooth, bubble free finish.

A heat gun helps the decal conform to curved or textured surfaces, while a squeegee removes trapped air. Professional tools make the difference between an average result and a clean polished finish.

Mistake 8: Designing Without Scale or Real World Context

A logo that looks great on a computer screen might not translate well on a vehicle, machine, or product.

Always consider scale, distance, and surface shape when designing custom emblems or decals. Creating a full scale mockup before production can prevent costly reprints and ensure your design has the impact you want in real world applications.

Mistake 9: Skipping Samples or Prototype Testing

Skipping samples is one of the costliest shortcuts. A sample or prototype allows you to confirm color accuracy, finish quality, and adhesion before placing a full order.

At Auld Tech we test every new product under real world conditions to ensure it performs as expected. Taking this extra step up front saves time, money, and frustration later.

Mistake 10: Ignoring Professional Input

The biggest mistake of all is trying to go it alone. There is real science behind custom emblem and decal manufacturing, including adhesives, materials, coatings, and curing.

Working with experienced professionals ensures that your project is done right the first time. Our team at Auld Tech has spent decades perfecting the art and science of domed emblems, labels, and decals that not only look great but also last.

Final Thoughts: Make Your Custom Emblems and Decals Last

The difference between a decal that fades quickly and one that looks great for years often comes down to small details. The right materials, preparation, and installation techniques ensure your brand looks professional and lasts through the toughest conditions.

Whether you need domed labels, raised emblems, industrial decals, or custom cut graphics, take the time to do it right. Quality design and manufacturing will always make your brand stand out for the right reasons.

The Science of Durability: Labels Built for the Harshest Environments

The Auld brand has been building brand identity elements (domed for more than 150 years). With that kind of history, you [...]

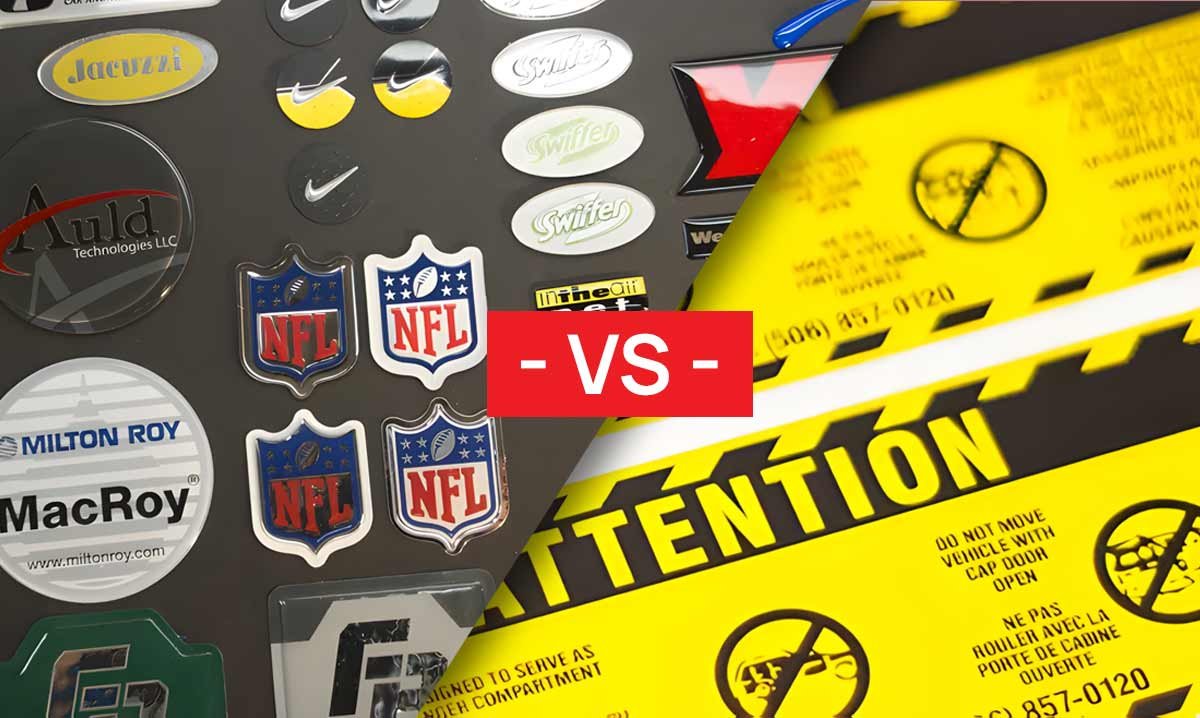

Domed Labels vs Flat Decals: Choosing the Right Option for Your Application

One of the most common questions I get is simple on the surface but important in practice. Should I use a domed label or a flat decal? [...]

Common Industries That Benefit Most From Domed Labels and Emblems

One of the things I enjoy most about this business is seeing where our work ends up. Over the years, I have watched domed [...]

Back

Back